Polymer Floor Tiles – Tiling Innovation

The LEED rating (Green building rating system) during these days for buildings is unleashing creativity among Architects and Engineers. One of the main goals for green building will be Material Efficiency. As a component of Green building – Environmentally preferable building material and Waste reduction are the important twin objectives that we should look at. The polymer Floor tiles used for indoor and outdoor applications could also enhance the ability to achieve LEED rating.

The challenge to be addressed:

Ability to explore design options for the indoor tile and pedestal using “various recyclable polymer material options.” The design is expected to address the challenge of material efficiency, reduced wastage, and meet all the performance needs, thus becoming a component to enhance green rating.

How this Challenge was addressed:

Designing plastic tile and pedestal system by itself was not a big challenging task, but to do it adopting virtual validation and math model-based engineering in the shortest span of time, was certainly an interesting challenge. The task was not only to use math model-based engineering to select a particular design but also to optimize it without having to build and test a physical prototype. The other part of the challenge was to make it work for both indoor and outdoor applications.

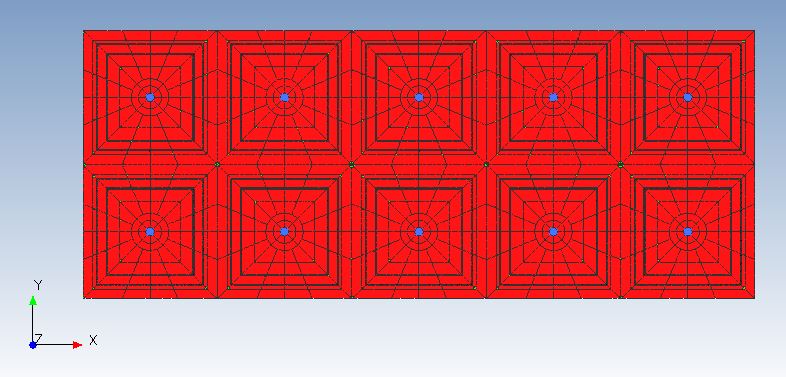

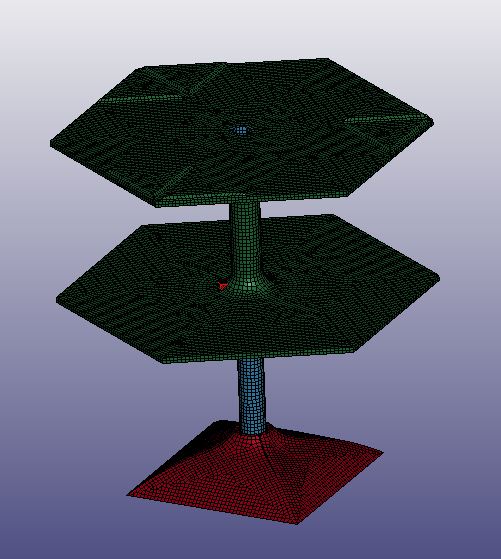

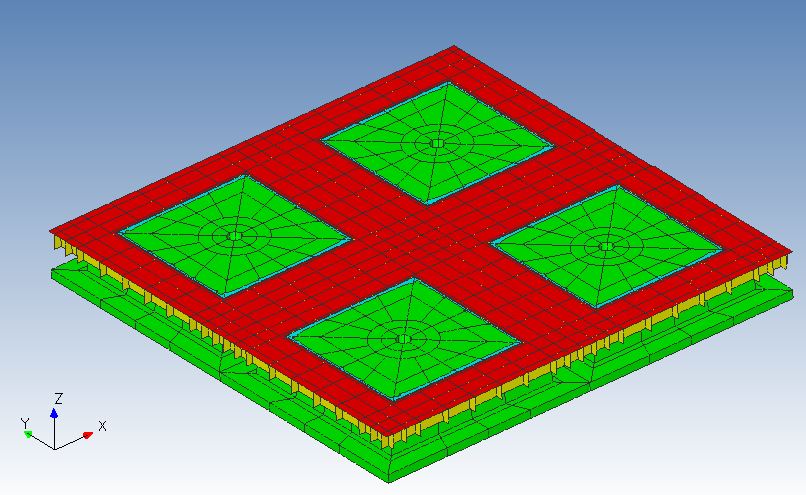

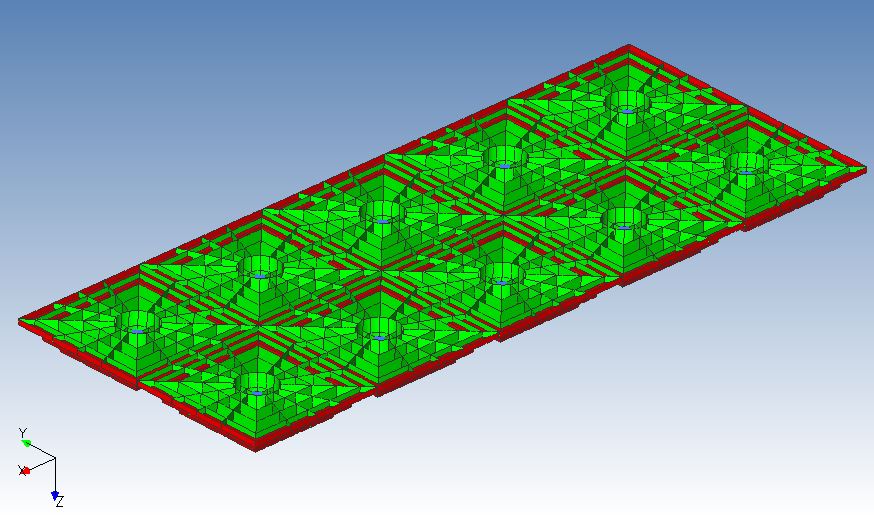

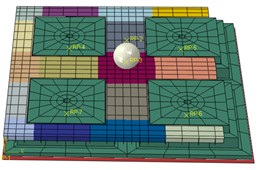

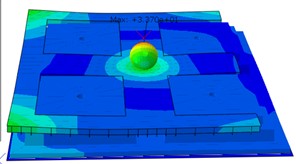

With inputs from the Architects and Civil Engineering team, the CAD models of several possible floor tile patterns and corresponding pedestal supports were created. The merits of each of those designs were debated and brainstormed all the way, till the process of laying them out in different shapes and size floor spaces. Each of those floor tile and pedestal systems was modeled and analyzed using Finite Element Models. FEA, being a virtual validation technique was able to analyze all the loading conditions including the dynamic loading like drop tests and ultimate loads, thus catering to both indoor and outdoor use cases.

Material choices were also examined using FEA models to narrow down to the right candidate and recycled properties were also included for performance check. The FEA results data were obtained for all the designs and each of the designs was compared for their merits. The Design comparison included deflection, deformation, and induced stresses as metrics to establish the load-carrying ability.

The design that really performed very well was found to be heavy in terms of mass compared to others. This triggered the process of optimization. Topology optimization and topometry optimization were used to explore efficient tile stiffening patterns down to the thicknesses required, considering manufacturing feasibilities. These predictions from the optimization exercise were discussed with manufacturing engineers to ensure manufacturability/moldability and cost to manufacture the tiles and pedestals. The optimization method illustrated the ability to save up to 20% mass without any performance drop.

All these discussions and decision-making were based on math model data and results from virtual validation without having to build prototypes and test them. This cycle of the study was very quick and saved at least 30% time and costs, which is certainly significant.

After all boxes were ticked in terms of recycled material use as intended, reducing waste while laying tiles, low per piece cost and performance were met. The design was released for prototype build. This process demonstrates the potential to add value to the green rating for buildings along with the contribution from floor tiles and pedestals. The floor tile and pedestal system designed has provision to facilitate cable routing and leveling system to adjust the height easily so that it adds to functionality and aesthetics.

The detailed Math model Engineering & Optimization study of floor tiles was conducted by the Engineering consulting division of APSG Engineering Private Limited, Bangalore (www.apsgengineering.com), and the project was led by Karthik Shankaran, Co-Founder & Director – Consulting Solutions. The Engineering & Optimization software tools used by Karthik & team are Genesis from Omniquest, USA & Design toolkit from GRM Consulting, United Kingdom.

Conclusion:

It was possible to explore and demonstrate that recycled material-based floor tiles and pedestals could help in material efficiency and reduction in wastage, as components of green rating and sustainability. The math model-based virtual validation helps to achieve the objectives without any performance loss and slashes the prototype build and testing expenses significantly.

About APSG Engineering:

APSG Engineering Pvt. Ltd., was formed during the year 2016 with the core objective of creating sustainable, planet-friendly & health-friendly products. APSG Engineering is based out of Bangalore, India, and focuses on product development, product distribution & engineering consulting solutions.

APSG’s vision is to be in the league of the greatest and kindest organizations that contribute to protecting the environment, as well as manage the resources for the forthcoming generations.

At this moment APSG is working with some of the premier organizations on consulting & product development solutions. The firm is conceptualized and is working to develop planet-friendly, health-focused & waste management products. They are also involved in the process of development and distribution of engineered fitness products

Author of the article, Kartik Shankaran, Co-founder & Director – Consulting Solutions

Kartik Shankaran has over 22 Years of experience in the area of Engineering, Simulation, and Optimization. He has managed Engineering Programs for about 9 years in the USA with organizations like JCI Tech Center Plymouth, GM Warren Tech Center, and Magna Powertrain East Syracuse, etc.

Over a period of time, he has also led several Automotive & Non-Automotive (Healthcare, Electronics, Heavy Engineering, Agricultural Machinery, etc.) and Engineering and product development programs across customers in North America, Europe, and the Asia Pacific.

At APSG, Karthik heads the engineering consulting strategic business unit and is responsible for consulting on in-house as well as customer programs.

Karthik can be reached at [email protected]

*The views expressed in this paper/article are those of the authors and do not necessarily reflect the views or policies of The Tiles of India.

GIPHY App Key not set. Please check settings